Beyond the Benchtop: Top 3 Maker & Digital Fabrication Trends of 2026

The future of home manufacturing is smarter, greener, and more precise. From AI-generated CAD to combining 3D printing with CNC precision, discover how these game-changing trends are empowering the modern maker.

The lines between professional industrial labs and home workshops are blurring faster than ever. In 2026, the "maker" identity has shifted from simple hobbyist to "micro-manufacturer." By analyzing the latest search data and community innovation, we’ve identified the three pillars defining the digital fabrication landscape this year: Hybrid Manufacturing, AI-Native Design, and Sustainable Materials.

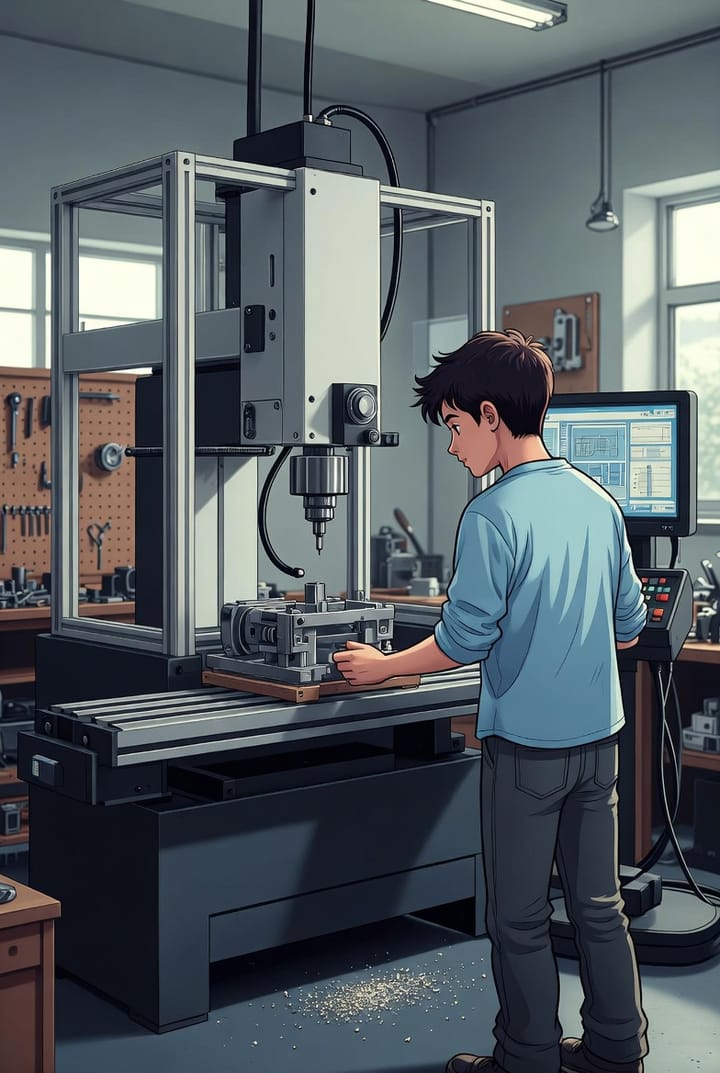

1. Hybrid Manufacturing: The Best of Both Worlds

The single most significant shift we’re seeing is the convergence of 3D printing and CNC machining. Makers are no longer choosing one or the other; they are integrating both into a single workflow.

This approach leverages the speed of additive manufacturing to create a "near-net shape"—a part that is roughly the right size—followed by the precision of subtractive post-processing. By using desktop CNC finishing, makers can achieve mirror-like surface finishes and mechanical tolerances that 3D printing alone cannot reach.

Keywords like "re-zeroing 3D prints" and "metal filament CNC" are dominating forums as users seek industrial-grade results from their desktop setups.

2. AI-Native Design: Your Co-Pilot in Creation

Design software is no longer just a passive tool; it’s an active collaborator. The AI-Native Design trend has moved the community from "downloading" files to "prompting" them.

Tools like "Text-to-CAD" and "generative AI CAD" allow users to describe a functional need—such as a "lightweight drone arm capable of holding 2kg"—and receive a fully optimized, print-ready file. Beyond the design phase, AI G-code optimizers are now being used to predict print failures before they happen and adjust speeds in real-time. This ensures that every part is a "born-qualified part," verified for quality during the fabrication process itself.

3. Sustainable Materials: The Circular Workshop

Sustainability is no longer a niche interest; it’s a primary search category. The maker community is leading the charge in circular manufacturing by prioritizing home filament recycling systems.

Beyond recycling waste, the demand for eco-friendly inputs is soaring. "Carbon-negative resin" is a top search for resin printing enthusiasts looking for plant-based, non-toxic alternatives. We are also seeing a massive spike in interest for bio-based composites and techniques like "vapor smoothing PLA," which gives biodegradable plastics the professional look of injection-molded parts without the need for harsh chemicals.