The Best of Both Worlds: Why Hybrid Manufacturing is Exploding in the Maker Space

Tired of choosing between intricate geometries and pristine finishes? Hybrid manufacturing, blending CNC and 3D printing, is empowering makers to achieve the impossible, driving a surge in searches for integrated solutions.

For years, the maker community has navigated a fundamental divide: the additive world of 3D printing versus the subtractive precision of CNC milling. Each technology offers incredible power, yet each has its distinct limitations. 3D printers excel at complex, organic geometries and rapid prototyping, but often fall short on surface finish, material strength (for certain applications), and tight tolerances. CNC machines, on the other hand, deliver impeccable surface quality, superior material properties, and unmatched accuracy, but struggle with internal structures or highly intricate, overhang-laden designs.

Today, that divide is dissolving. There's been a massive spike in searches for "CNC + 3D Printer combo" and "subtractive vs additive" as makers realize they don't have to choose. The era of Hybrid Manufacturing has arrived, promising a synergy that allows for the creation of components previously deemed impossible for the home workshop.

Why the Fusion? It's All About the Impossible Part

The driving force behind this surge in interest is simple: makers want to build better, stronger, and more intricate parts. Consider a few common scenarios where traditional methods hit a wall:

- Complex Internal Features with Pristine Exteriors: Imagine a part with intricate internal cooling channels (perfect for 3D printing) but requiring a perfectly smooth, hard-wearing exterior surface with exact tolerances for mating components (a job for CNC). A hybrid approach can print the internal structure, then mill the exterior to perfection.

- Strengthening 3D Printed Parts: While 3D printing is fantastic for shape, the anisotropic nature of FDM prints can sometimes compromise strength. Printing a near-net-shape part and then CNC machining critical features or surfaces can drastically improve structural integrity, surface finish, and dimensional accuracy where it matters most.

- Multi-Material Integration: Certain hybrid machines are exploring ways to embed components (like sensors or metal inserts) during a 3D print cycle, then use the CNC spindle to create precise cavities or clean up the surrounding material.

- Rapid Iteration, Flawless Finish: Quickly 3D print a design iteration for form and fit, then use the same machine's CNC capabilities to mill a final, high-quality prototype from a solid block for critical testing or presentation.

The Machines Making it Possible

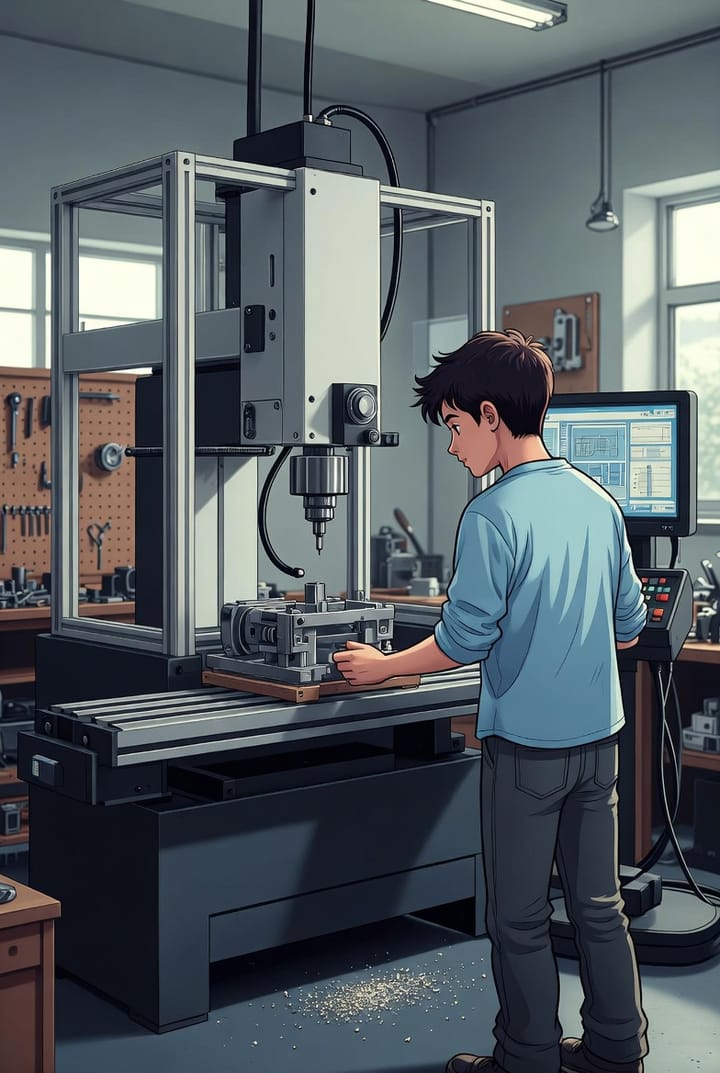

Initially, "hybrid manufacturing" meant having two separate machines in your workshop and moving parts between them. While effective, this process introduces setup time, potential for misalignment, and increased workflow complexity. The true game-changer is the emergence of integrated "combo" machines that can perform both additive and subtractive operations within a single build volume.

These integrated systems often feature quick-change tool heads: one for filament extrusion (or resin curing, in some cases) and another for a CNC spindle. This allows for automated transitions between processes, minimizing human intervention and maximizing precision. They leverage robust gantry systems and sophisticated motion controllers, borrowing heavily from the stable foundations of CNC machines to ensure accuracy even during additive processes.

Beyond the Hobbyist: Industrial Echoes

This trend isn't just confined to hobbyists. Industrial giants have been exploring hybrid manufacturing for years, particularly for high-value metal components. Think about additive manufacturing of complex turbine blades, followed by precision CNC machining of critical mating surfaces for aerospace applications. The lessons learned in industrial additive-subtractive workflows are now trickling down to the prosumer and small business segments, fueled by more affordable, yet highly capable, integrated platforms.

The "subtractive vs additive" debate is evolving into a more nuanced discussion: "subtractive and additive." Makers are no longer limited to the strengths of one technology. They are now empowered to design and produce parts that truly harness the best characteristics of both, pushing the boundaries of what’s possible in personal fabrication. This fusion isn't just a trend; it's the next logical evolution of the modern workshop, promising a future of unprecedented creativity and precision.