The Snapmaker Artisan: Review of the 3-in-1 Digital Fabrication System

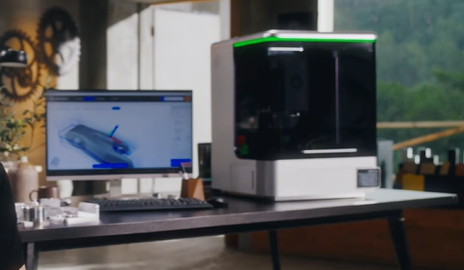

The Snapmaker Artisan is a third-generation modular machine offering a powerful combination of 3D printing, laser engraving, and CNC milling in a single desktop unit.

The desktop digital fabrication landscape is increasingly dominated by machines that offer versatility, and the Snapmaker Artisan is a prime example. As a successor in the Snapmaker lineup, this machine consolidates three primary manufacturing methods—Fused Deposition Modeling (FDM) 3D printing, high-power laser processing, and Computer Numerical Control (CNC) milling—into one robust, modular platform.

Core Features and Versatility

The Artisan's core value proposition is its ability to transition between specialized fabrication methods through its quick-swap module system. This design minimizes downtime and reduces the physical footprint required in a workshop.

1. Dual-Extrusion 3D Printing

The 3D printing module is a significant upgrade, featuring a dual independent extruder system. This allows for:

- Multi-Material Printing: Simultaneous use of different materials (e.g., rigid filament and flexible filament) in a single print.

- Soluble Supports: Utilizing soluble material for supports, which simplifies post-processing for complex geometries.

- High-Speed Operation: The system is engineered for increased print speed compared to previous generations, optimizing production workflow.

2. High-Power Laser Processing

The included 10W laser module provides substantial cutting power. This capability extends the machine's utility beyond simple engraving to include cutting through a variety of materials, such as thin wood, acrylic, and leather, making it suitable for tasks like sign-making, inlay creation, and rapid prototyping of flat parts.

3. Robust CNC Milling

The CNC module is designed for precision and material durability.

- Rigidity: The machine frame utilizes heavy-duty linear rails and a more stable structure, which is critical for CNC operations. This enhanced rigidity is essential for reducing vibration and maintaining tool-path accuracy when machining harder materials.

- Material Compatibility: It is suitable for machining common workshop materials including various woods, composites, plastics, carbon fiber, and softer metals like aluminum.

Operational and Design Factors

| Feature | Detail | Impact on User |

| Work Area | Larger build volume than previous models. | Increased capacity for bigger projects or batch production. |

| Construction | Heavy-duty modular linear rails and durable components. | Improved precision, longevity, and stability during high-force CNC operations. |

| Software | Managed via the proprietary Luban software. | Unified interface for G-code generation, slicing, and laser/CNC path creation. |

| Enclosure | Optional full enclosure available. | Addresses safety concerns (laser light, dust, noise) for home or educational environments. |

The Snapmaker Artisan is positioned as a generalist solution for makers who require versatility and space efficiency. Its modular nature directly contrasts with dedicated machines, such as highly rigid, single-purpose desktop CNC mills (like the Makera Z1 or Nomad 3) which prioritize maximum precision and speed in one specific task.

For users who frequently switch between design stages—from 3D-printed mockups, to laser-cut panels, to CNC-milled final parts—the Artisan offers a comprehensive and streamlined workflow that mitigates the need for multiple expensive, single-function tools.